Solar cell technology has been around for over sixty years. Solar modules, commonly known as pv panels, happen to be applied to generate electrical power from light since the silicon based semiconductor was developed. No longer the laboratory curiosity, solar cells are the industry unto on their own and are since common in energy generation as conventional power generation strategies such as heavy steam turbine driven power generators and nuclear power plants. There happen to be many solar power collection methods utilized and available right now. We will investigate the particular more common electrical energy producing solar strength devices: photovoltaic tissue and PV segments.

How does the PV module create electricity from light-weight?

Solar Cell

Solar cells are built of materials that will are electrically triggered when light hits their surfaces. This unit, a solar cell, operates with no moving parts and not wears out! Put many cells jointly and you have got a solar variety or a pv module. The more cells, the higher the power that is certainly possible to create from the modules.

Mobile Tiers

The best layer from the solar cell or wafer contains a si layer which has got free electrons which usually are negatively incurred particles. A boron enhanced bottom part contains spaces or holes, that permit electrons transfer to the open spaces. Typically the manufacturing process creates this electron imbalance between the a couple of layers within this semiconductor material. This imbalances is dependable for the operation of the solar cell which generates the electrical latest and voltage.

The particular Sun Strikes typically the Solar Cell

Photons from the sun hit the outdoors of the solar cell. This activity excites the no cost electrons in both silicon layers. Some bad particals in the bottom layer travel to the silicon layer near the top of the mobile. Electron flow moves through metal contacts situated on the solar cell's front and back which creates electrical power. Electrons flow in a closed loop or electric circuit. Combining several solar cells provides an additive effect on voltage and current depending about how they are "strung" jointly. Think of every cell as the battery. Stringing the particular cells in series (negative to positive) will add volt quality and keep amperage just like for one particular cell. Stringing the particular cells in parallel will keep voltage just like for 1 cell but add the amperage of the cells.

At the rear of With Solar

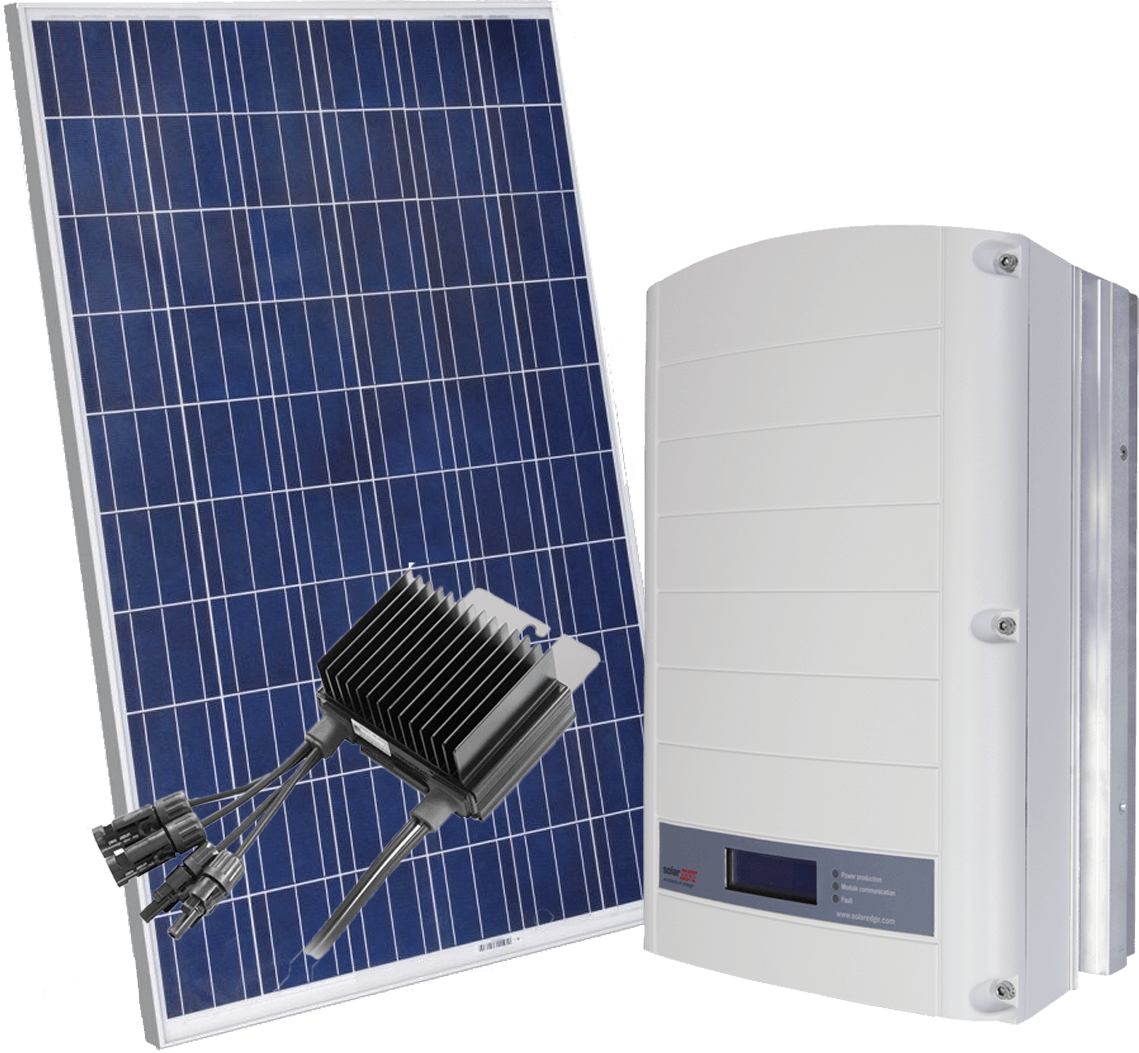

Solar panels generate electric current which is transmitted to a great inverter. The inverter changes direct current straight into alternating current which matches the electricity that your power business provides. Appliances in addition to power equipment work with AC present. In the Combined States, power is definitely generated at 70 hertz whereas in Europe, 50 hertz is the usual.

The solar electrical power feeds into typically the wiring of the house, business or perhaps power plant and even into the electrical utility's power grid. An independently run power system furthermore can act because its very own utility. This "off-grid" system calls for batteries to retail outlet power if the solar panels produce even more power than the load needs and even is discharged when the solar quests cannot capture enough energy from typically the sun to balance the electrical lots from your household or company.

Converting Silicon Wafers Into Photovoltaic Tissue

The pc chip industry has made the lower cost production associated with the solar mobile possible. The strides in yield, digesting and quality make the photovoltaic cell manufacturing process existing state-of-the-art and international. While the process is matures for silicon wafer manufacturing, the techniques are usually frustrating and essential in achieving the desired performance effects. The silicon wafer starts out as an ingot of silicon material and after that is sawn straight into the characteristically game wafers that you find on a solar module.

EtchingA Wafer

The part of the solar mobile process requiring some sort of clean room features chemical and temperature treatments that switch the greyish silicon wafers into reside, blue colored tissue. A chemical etching removes a little coating of silicon. Beneath this layer, some sort of crystal structure reveals a pyramid designed surface that absorbs more light.

Diffusing

Silicon wafers are placed into stoves where phosphorus is diffused into typically the wafer surface. This particular step deposits a molecular sized deposit as the wafer surface is confronted with phosphorus gas at the high heat. This step shows the surface a negative prospective electrical charge. This kind of layer and the particular boron-doped layer below the surface make a positive-negative, or perhaps P/N, junction which is the basis regarding a PV cellular. This is likewise what sort of semiconductor nick is done.

Coloring And even Publishing

The tissues are placed in to vacuum chambers exactly where silicon nitride is usually deposited onto the part of the wafer that is to be exposed to the particular sunlight. The covering with silicon nitride is designed to reduce light representation. This method gives the particular cell its dark blue color. The particular cell is ready to produce electricity however will need a means to be able to collect and frontward the power to typically the load. Metal beating are printed on both sides from the cell so that will electrical charge series and landing areas for wires can easily be added to typically the wafer. When this kind of step is finish, the cell is able to produce power.

Connecting https://bsolarenergy.co.uk/ Into Solar Panels

Cells are arranged to produce the voltage and amperage profile involving the completed solar panel. If you look at the various brands regarding solar panels about the market, you will notice that the cell arrangement dictates each of these attributes of home solar sections and commercial sort solar panels. Subsequently, the physical frame size of the particular PV module will be set from the solar cell arrangement.

Soldering

Cells are soldered together into sequence strings which involves power bonding of the wafers together to create one module. Several strings are linked to kind a rectangular matrix of cells. Each cell matrix is laminated onto glass using a solid adhesive system that ensures the finished panel will survive normal environmental lots.

Framework

The external frame in the solar module provides safety against weather and impact loads as well as includes the electric powered connection which can certainly be a junction field or perhaps a standard electrical cable connector. These kinds of are widely used found in other electrical equipment.

Location, Location, Place

Siting the solar module array demands the chance in order to collect as much sun rays as possible throughout the seasonal variation inside sun intensity.

Rooftop systems provide the ready platform considering that the surface is certainly often tilted in the direction of the sun plus the surface is certainly unusable for many any other device.

Ground-mounted systems are fine options where homes are unavailable or too small in area. Modules are usually mounted on racks which in turn are ground moored and accessible with regard to service or putting additional solar segments.

Canopy systems job well in shed roof applications for instance parking areas.

Utility-scale systems are normally mass power producing units that are usually sized for energy grade use in addition to not usually in short supply in land region.

Tracking systems optimize output power by simply moving the solar modules according to be able to the sun's path.

Summary

Solar segments are an marriage of solar tissue and the technologies which makes computer chips cheaper than present a decade ago. The inherent trustworthiness of the solar modules used intended for home solar sections is due to the possible lack of moving pieces as well as the high dependability parts and operations that make the solar module reality. Generally there are no restricts to the forms of solar electric techniques that can be designed and incredibly handful of limitations on spot as long since there may be abundant sun light.